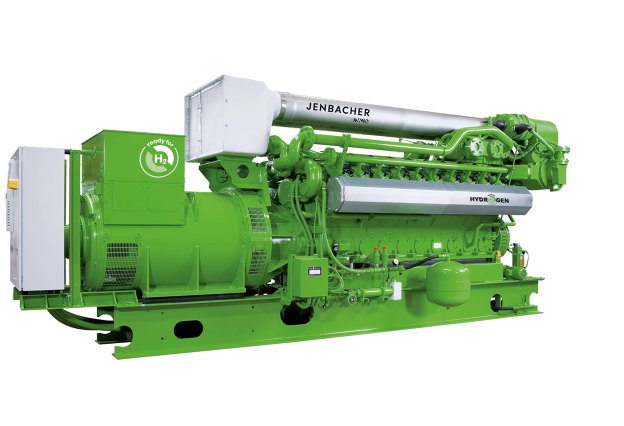

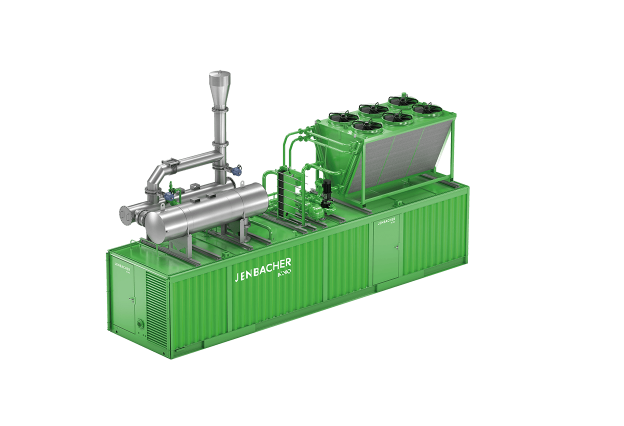

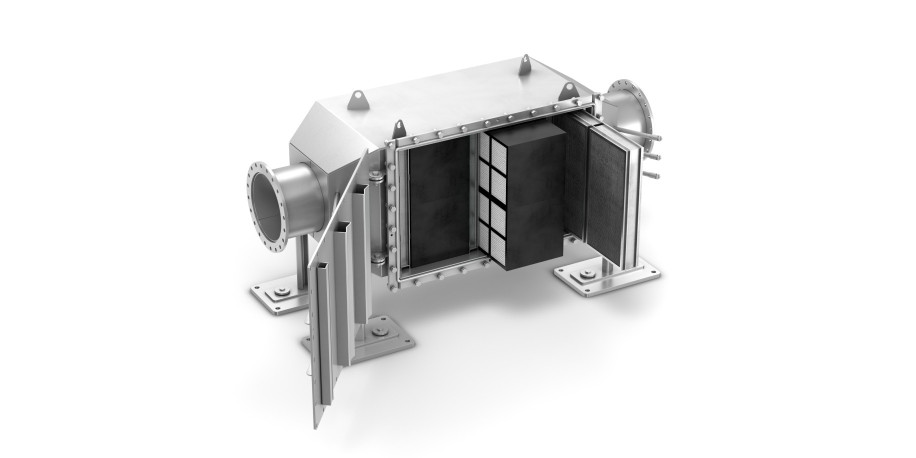

Long service intervals, a maintenance-friendly engine design, and low fuel consumption ensure maximum efficiency, while enhanced components prolong service life—even when employing non-pipeline gases such as landfill gas. ~10,700 engines delivered since 1988.

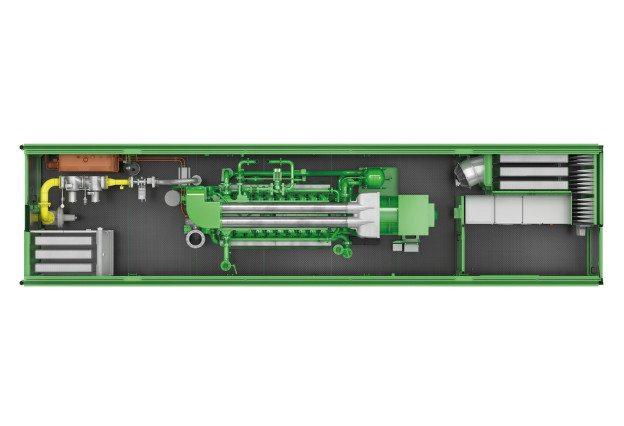

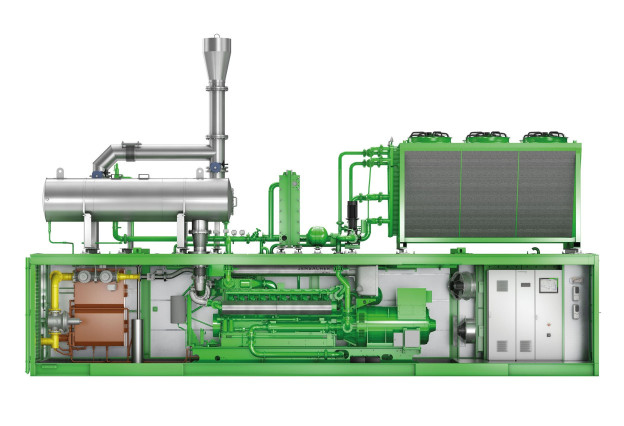

Scope of supply:

50 Hz

60 Hz

Jenbacher can change the technical data unilaterally. In the case of such change, we will update the data on our pages as soon as we can.

Please reach out to our experts to get help with engines selection, obtain the technical parameters for your gas composition.

Output and efficiency at generator terminals. Energy input is according to DIN ISO 3046 and DIN 6271, respectively, with a tolerance of + 5%.

All data according to full load and subject to technical development and modification.

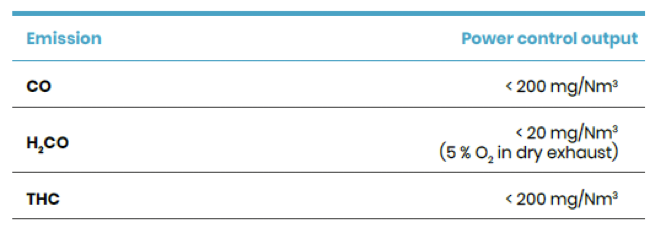

Based on emission values of 250 and 500 mg/Nm3 NOx at 5% O2 at dry exhaust gas.

Base for biogas and sewage gas versions: 65% CH4 / 35% CO2.

Base for landfill gas version: 55% CH4 / 40% CO2 / Rest N2.

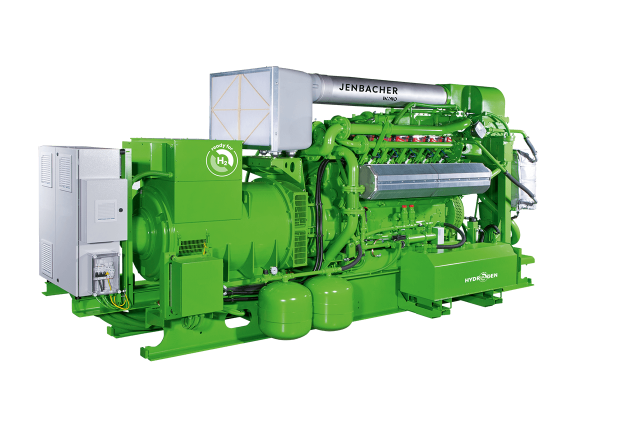

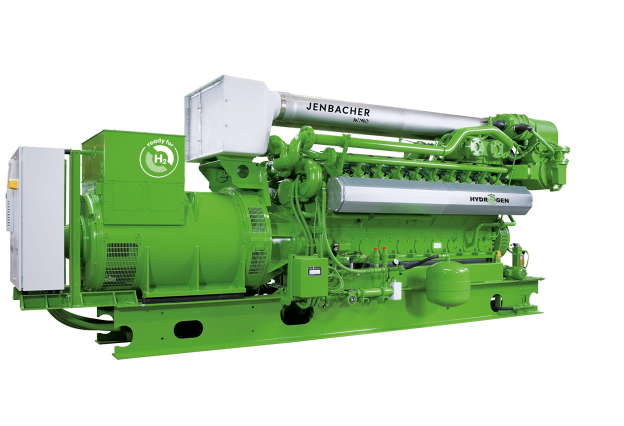

Electrical Output635 - 1,062 kW

Thermal Output804 - 1,399 kW

Voltage480V - 4.16kV

Electrical Efficiencyup to 39.2 %

Thermal Efficiencyup to 50.7 %

Discover models: