Containerized Solutions

Integrated Solutions.

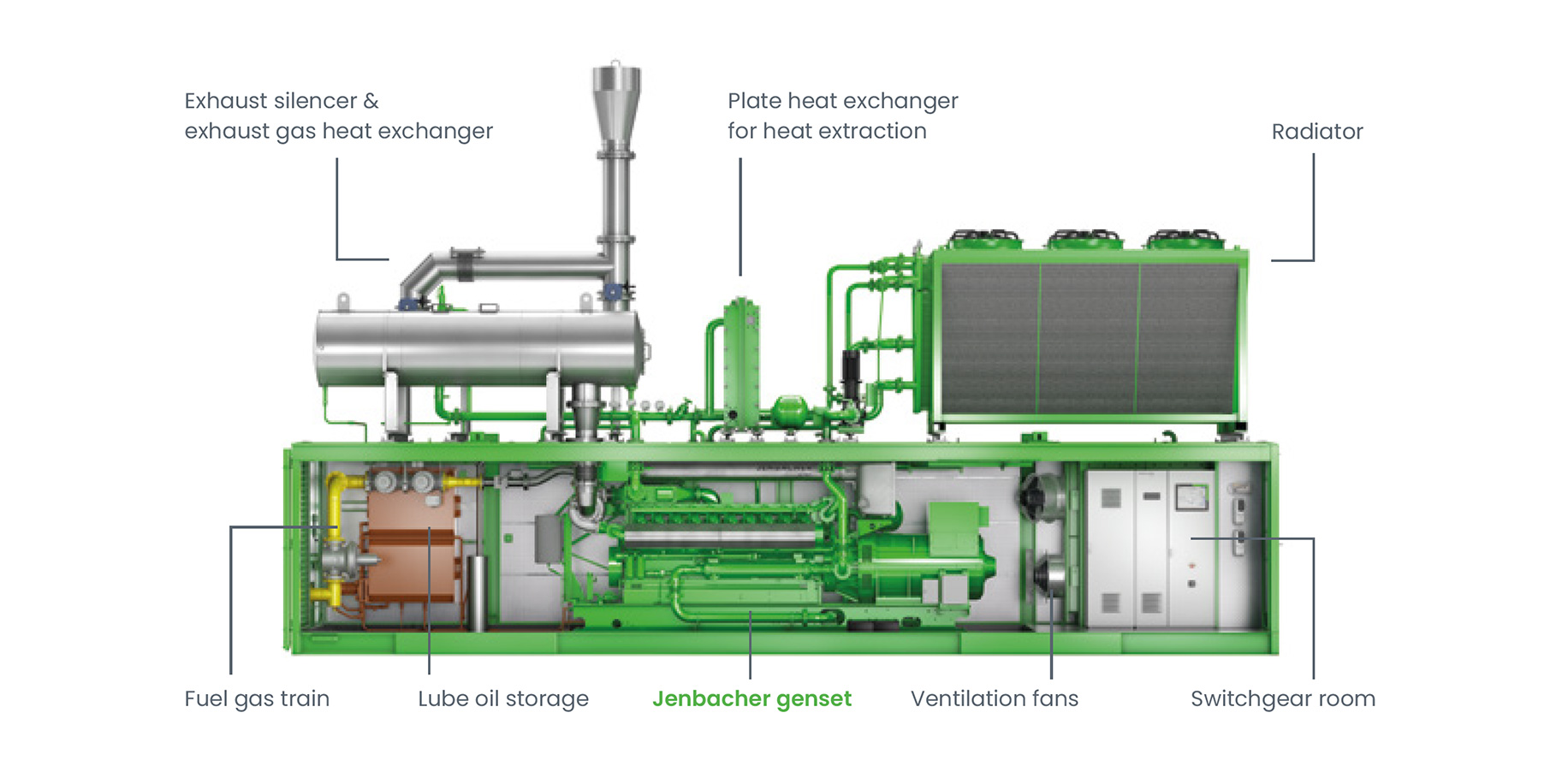

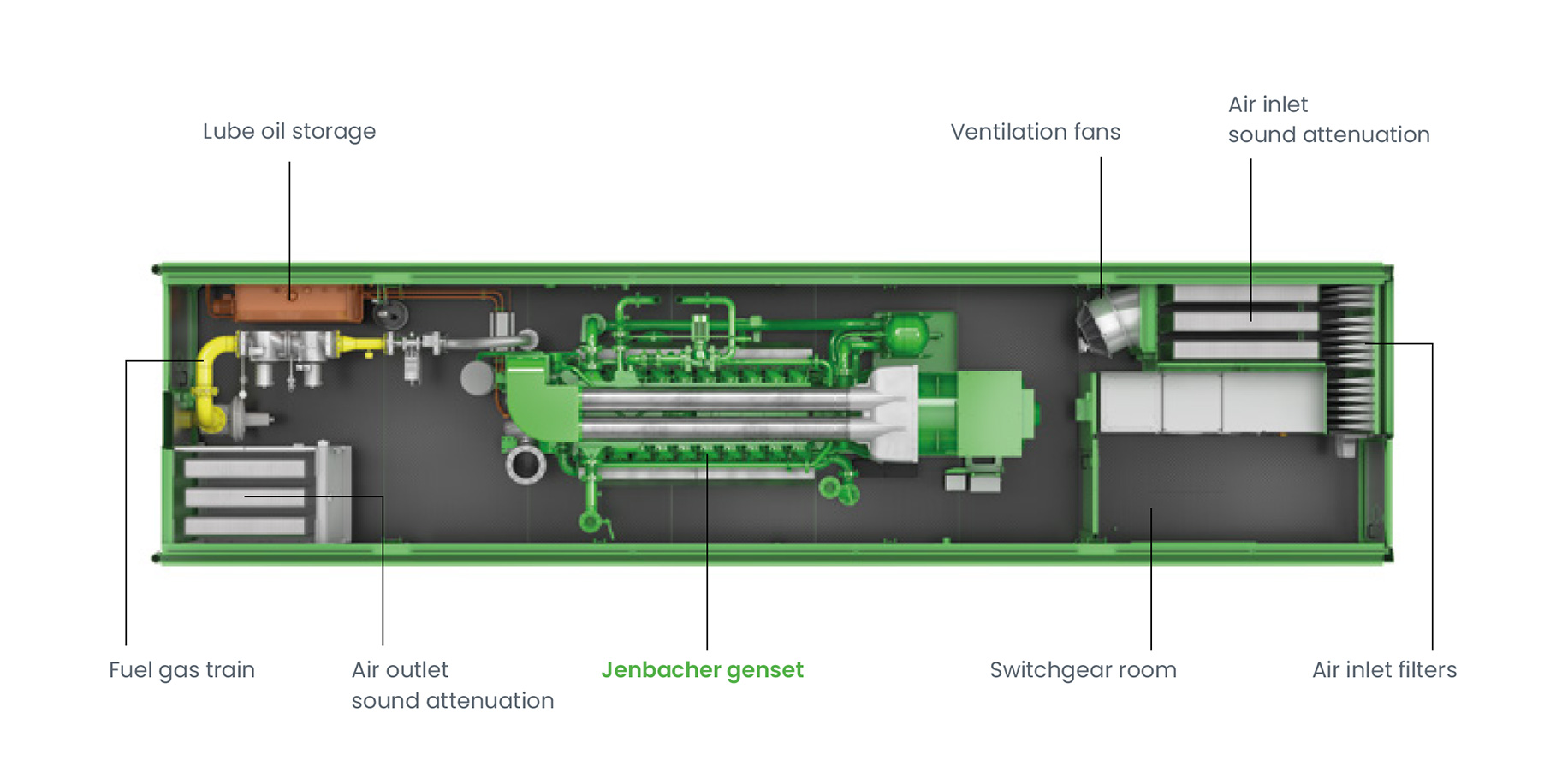

Jenbacher containers are available for Type 2, 3, 4 and 6 gas engines. Based on the expertise gained in several decades with over 3,000 containerized units delivered, our genset containers offer optimal performance in various site conditions. By applying the same high quality standards to the complete package as to the engine, our containerized solutions ensure excellent reliability for your power and heat generation needs.

Jenbacher containerized solutions offer a variety of benefits to our customers, thanks to distinctive product features:

Product features |

Customer benefits |

|

|

|

|

|

|

Roomtour of our 100% hydrogen Jenbacher container

See for yourself. Join Henning Liepelt, our Product Manager for Containerized Solutions, as he takes you on an exclusive tour of INNIO's pioneering Jenbacher containerized energy system, designed for 100% hydrogen operation. Get ready to step into the future of sustainable energy solutions!

Find out more about our hydrogen solution here.

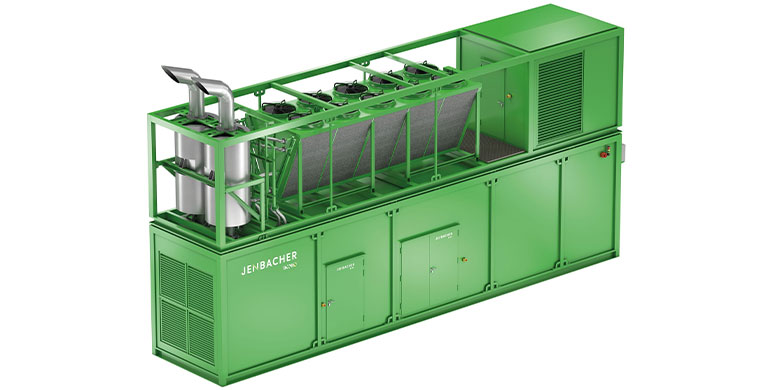

Containerized Solutions for Type 2, 3 and 4 (249 – 1562 kW)

Compact, easily transportable format

Containers for Type 2, 3 and 4 have a standard 40-foot length. Width and height depend on engine type, the application (power generation only or CHP) and ambient conditions.

Customized sizes to accommodate special project requirements are available on request.

|

Type 2 and 3 |

Type 2, 3 and 4 |

Type 4 |

|

|---|---|---|---|

| Length |

12,192 mm |

12,192 mm |

12,192 mm |

| Width | 2,438 mm 8 ft |

~3,000 mm 10 ft |

~3,000 mm 10 ft |

| Height | 2,591 mm 8 ft 6 in |

2,591 – 2,700 mm 8 ft 6 in – 8 ft 10 in |

2,896 mm 9 ft 6 in |

Features and options

Sound attenuation

Sound attenuation

The overall package (container and auxiliary components) is designed to meet 65 dB(A) in 10m (surface sound pressure level according to DIN 45635). Lower sound pressure levels are available on request.

Ambient temperature

Ambient temperature

The standard ventilation is designed for ambient temperatures from -25°C to +34°C.

All containers are also available with an option for -40°C and most variants can be upgraded for +45°C.

Options

Options

A broad range of options, both mechanical and electrical, are available to ensure that our containers meet the project requirements. For example, we offer several heat recovery configurations and exhaust after treatment systems. Our containers can be designed to meet different country-specific regulations, earthquake safety requirements and various ambient conditions.

Experience our webinar to learn more about Jenbacher's CHP solutions

Jenbacher North American team invites you to review the recording of our recent webinar, to learn how Jenbacher can help you develop your power plant projects, including equipment design and performance, using hydrogen and much more!

In the webinar, you will learn more about:

-

Overview of an independent power plant and its components

-

Jenbacher’s highly efficient type 6 genset

-

Our hydrogen power generation solutions

-

How proven equipment design improves performance

-

Power generation solutions with quick delivery and easy installation

The information provided is relevant for the North American market. Please reach out to our experts to discuss your project.

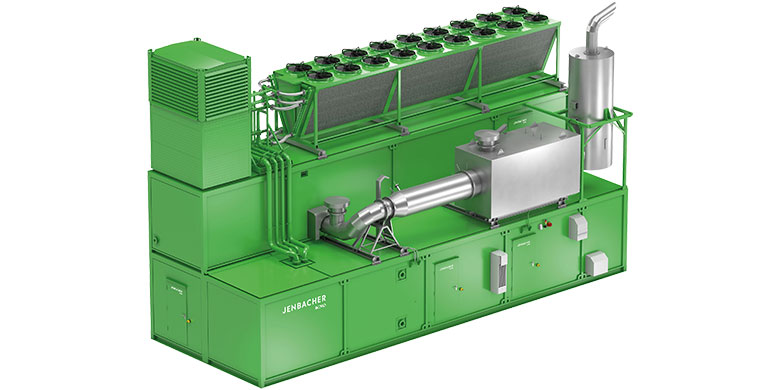

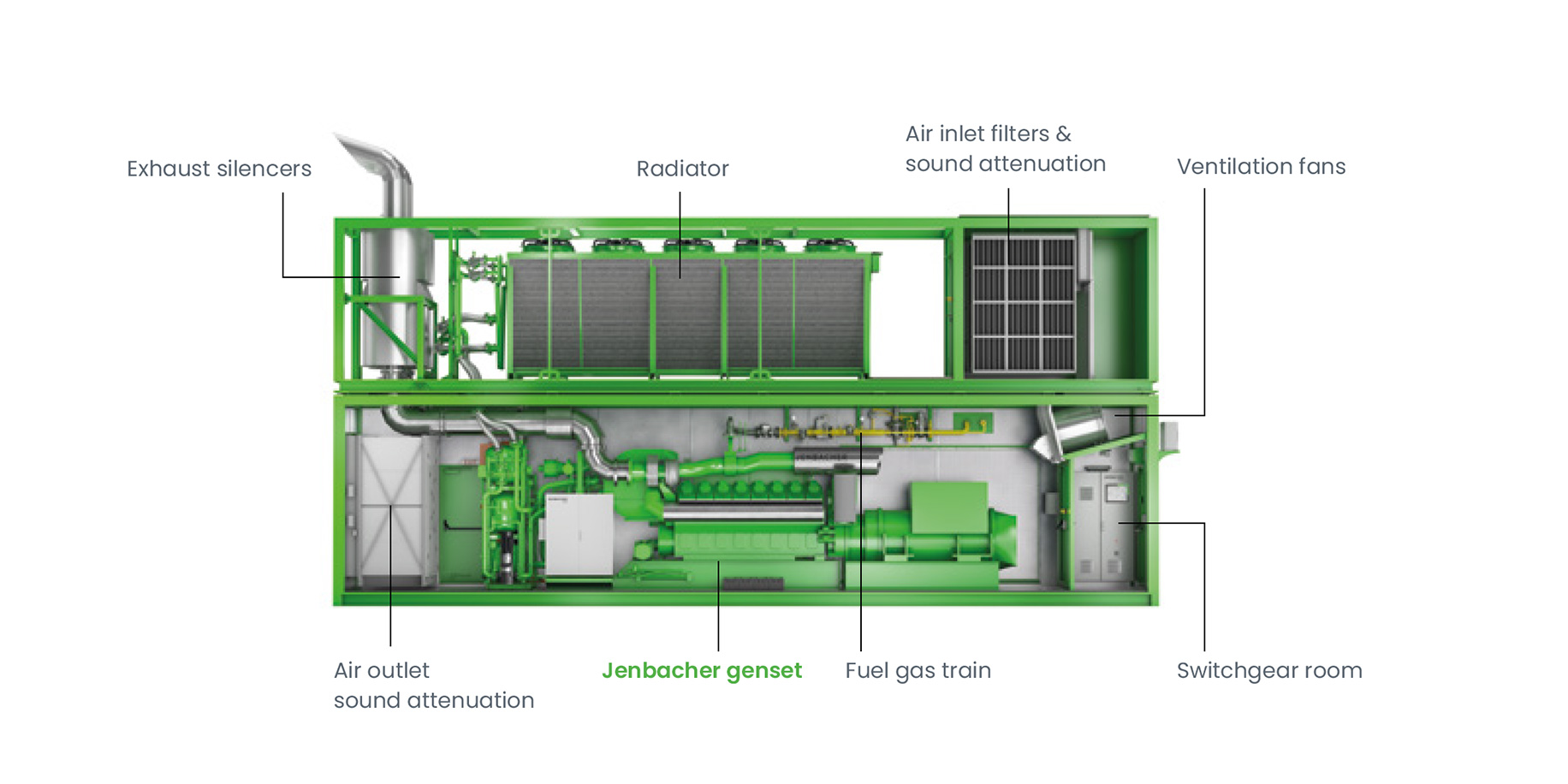

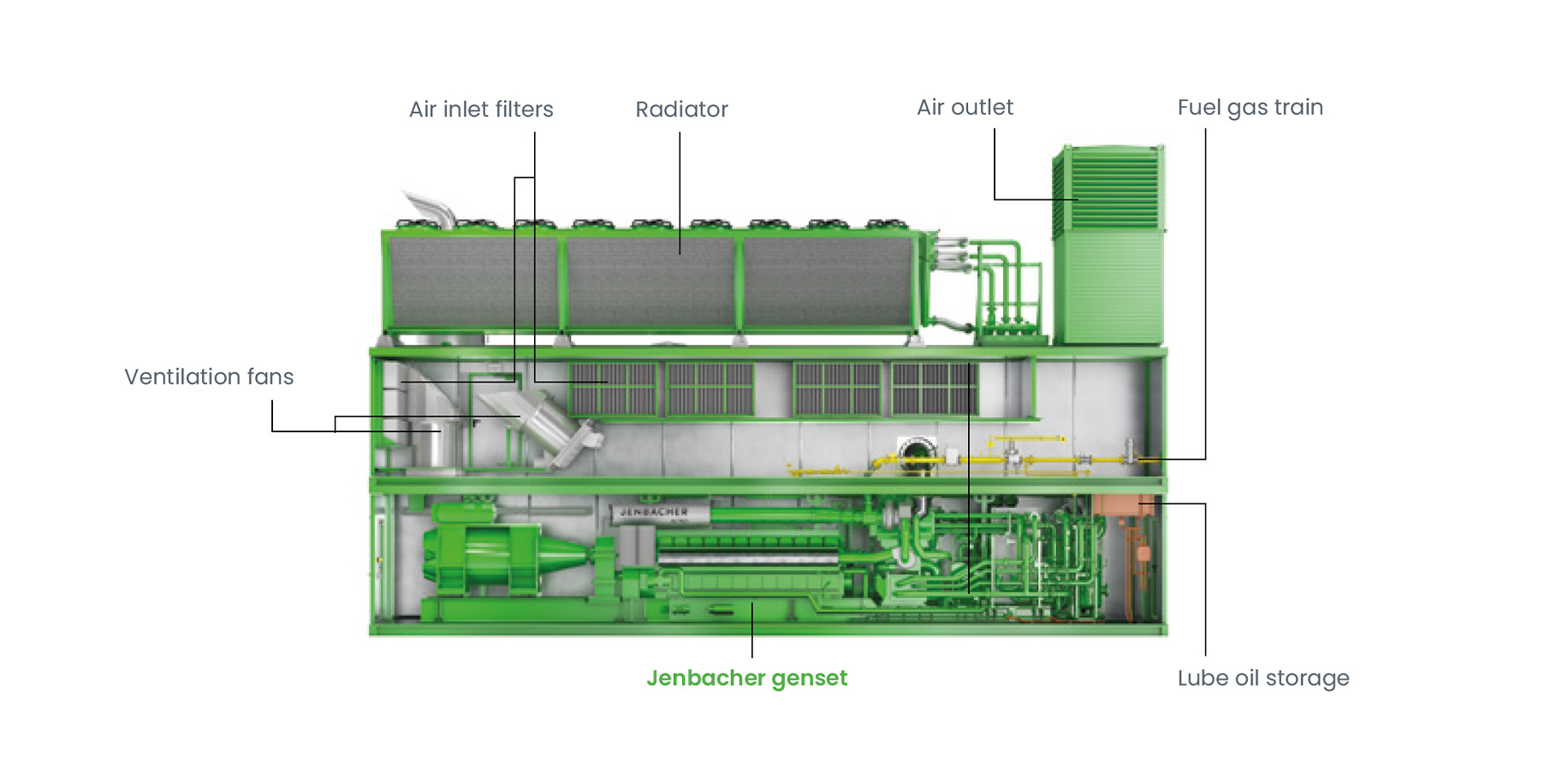

Containerized Solutions for Type 6 (1634 – 4507 kW)

Pre-assembled modules

Containers for Type 6 consist of two or three pre-assembled modules, depending on the engine type and the application.

|

Engine Type |

Application |

|

|---|---|---|

|

2-Container Layout |

J612 -GS, J616 -GS, J620 -GS | Power Generation |

|

3-Container Layout |

J624 -GS | Power Generation |

| J612 -GS, J616 -GS, J620 -GS, J624 -GS | Heat & Power Generation |

|

Length |

Width |

Height |

|

|---|---|---|---|

|

2-Container Layout |

13,500 – 20,500 mm ~44 ft – 67 ft |

3,000 – 4,000 mm ~10 ft – 13 ft |

~7,500 mm ~25 ft |

|

3-Container Layout |

|||

| 12,000 – 19,500 mm ~41 ft – 64 ft |

6,000 mm ~20 ft |

~7,500 mm ~25 ft |

*Main unit dimensions without roof-mounted equipment

Features and options

Sound attenuation

Sound attenuation

The overall package (container and auxiliary components) is available for 65, 70, 75 and 80 dB(A) in 10m (surface sound pressure level according to DIN 45635). Lower sound pressure levels are available on request.

Ambient temperature

Ambient temperature

The standard ventilation is designed for ambient temperatures from -25°C to +40°C. The containers can be equipped with several additional features to enable operation at lower temperatures on request.

Options

Options

Type 6 containers are available with a similarly broad range of options that we offer for the Type 2 / 3 / 4 containers. These include several heat recovery configurations, exhaust after treatment systems, compliance with country-specific regulations, earthquake safety requirements and various ambient conditions. Additionally, several Type 6—specific options are available, such as the integration of pre-chamber gas compressors and medium voltage equipment.

Experience our webinar to learn more about Jenbacher's CHP solutions

Jenbacher North American team invites you to review the recording of our recent webinar, to learn how Jenbacher can help you develop your power plant projects, including equipment design and performance, using hydrogen and much more!

In the webinar, you will learn more about:

-

Overview of an independent power plant and its components

-

Jenbacher’s highly efficient type 6 genset

-

Our hydrogen power generation solutions

-

How proven equipment design improves performance

-

Power generation solutions with quick delivery and easy installation

The information provided is relevant for the North American market. Please reach out to our experts to discuss your project.

Our experts are ready to help you!

Looking for onsite power solutions? Check.

Need access to electricity? We’re there for you.

Want to lower your energy costs, or even sell electricity back to your local grid? Check … check.

INNIO’s regional experts can help you figure out the Jenbacher solution that best meets your needs. With a free consultation, you can:

- Explore the advantages of onsite power generation solutions for your company

- Discover how to use economic modeling for added financial benefit

- Get answers on the technical aspects of your project—including fuel types, feasibility studies, and equipment and balance of plant selection

- Learn how to take advantage of regional incentive programs

- Review the delivery options for your project: purchasing, financing, leasing, and engaging a service provider, such as ESCO or BOO

- Find out how to meet emissions targets

Fill out the following contact form or send us an email to contact.en@innio.com. Let's get started!

Resources & Downloads

Jenbacher Webinars – Designing Your Power Plant (2022)

Language: English

Category: Webinars

Jenbacher Webinars – Designing Your Power Plant JBCOM

Consult an expert

Send us a message and we’ll contact you to start the conversation.

Whether your business is looking for onsite power solutions, access to electricity, decreased energy costs, or even to sell electricity back to your local grid/consumers, Jenbacher regional experts can advise you on which solution makes the most sense for you.