Gas engine and gas turbine technologies: Overview

Comparing two power generation technologies

In the ever-evolving landscape of power generation, two decentralized power generation technologies stand out for their efficiency and reliability: gas engines and gas turbines. Both offer the advantage of reducing reliance on long distance electricity transmission and distribution, but each technology offers distinct advantages and specific applications. Understanding the major differences can help you make informed decisions on decentralized power generation technologies.

Gas engine technology

These internal combustion engines operate on gas fuels to generate electricity. They are widely used in power plants, industrial facilities, and other sectors where reliable, on-site power generation is needed.

What is the typical gas engine power plant scope?

- Gas engine: The heart of the generator set (genset), it operates on the principle of internal combustion, where either a gas-air mixture is ignited or fuel is injected via a direct air-injection system into the cylinders to produce mechanical energy.

- Generator: Coupled with the engine, the generator (or alternator) converts mechanical energy produced by the engine into electrical energy. It consists of a spinning rotor within a stator that creates an electromagnetic field, inducing a current.

- Control system: The control panel, along with associated software, monitors and controls the genset operation. It enables the genset to operate safely, efficiently, and reliably – starting and stopping it, regulating the output voltage, and protecting the genset from overloads and other faults.

- Heat exchangers: By capturing the waste heat produced during electricity generation, the system’s overall efficiency is improved significantly. This otherwise wasted heat is repurposed for on-site heating, district heating, industrial processes, or even cooling (via external absorption chillers).

- Auxiliary equipment: This includes cooling, exhaust, fuel, start-up, and other systems.

These components work together to enable the genset to operate efficiently and reliably, providing a steady supply of electricity and heat, if necessary.

How does the gas engine work?

The process begins with the intake of a mixture of air and fuel – such as natural gas, biogas, or other gas fuels – into the engine’s combustion chamber. The mixture then is compressed by a piston and ignited by a spark plug. The resulting explosion drives the piston downward, turning the crankshaft and generating mechanical energy. This mechanical energy then is converted into electrical energy by an alternator. Dedicated engine versions also use direct port injection technology to improve both the combustion of fuels such as hydrogen and the engine’s transient performance.

INNIO Group offers a wide range of gas engine solutions that are designed for excellent efficiency, reliability, and flexibility. These engines can be used in a variety of applications, including power generation; CHP or cogeneration; and combined cooling, heat, and power (CCHP) or trigeneration.

Gas turbine technology

A standard gas turbine power plant has a scope similar to that of a gas engine plant. However, in this case, the gas turbine unit converts the energy from burning gas into mechanical energy to spin the turbine. This technology is widely used in power plants and industries due to its efficiency, flexibility, and reliability.

How does the gas turbine work?

- Air intake: The process begins with the intake of air, which is compressed, usually with a centrifugal or axial compressor.

- Fuel combustion: The compressed air then is mixed with fuel – typically natural gas or diesel – in a combustion chamber. The fuel-air mixture is ignited, producing high-temperature, high-pressure gas.

- Power generation: This high-pressure gas then is directed toward the turbine blades, causing them to spin. The spinning turbine is connected to a generator, which converts the mechanical energy into electrical energy.

- Heat recovery: Exhaust heat from the turbine can be used in heat exchangers to generate hot water or steam for various applications, a process known as cogeneration. In combined cycle gas turbine (CCGT) power plants, heat from the exhaust gas is used to produce steam, which drives a steam turbine to generate additional electricity. These processes significantly improve the power plant’s overall efficiency.

Gas engine vs. gas turbine comparison table

| Parameter | Gas Engine | Gas Turbine |

| Electrical efficiency (simple cycle) | 39 – 49% | 30 – 42% |

| Electrical efficiency (combined cycle) | N/A | 50 – 63% |

| Total efficiency (electrical + heat) | 80 – 95% | 75 – 85% |

| Exhaust heat available | 752 – 932°F | 842 – 1,202°F |

| Required gas pressure | < 7.25psi - 174.05psi | 290.08psi - 725.19psi+ |

| Start-up time | 45 sec – 5 min | 5 – 10 min; 30 – 60 min (CGT) |

| Start limitations | not restricted | 1-hour operation window needed |

| Time to load acceptance | < 15 sec | > 2 min until synchronization |

| Footprint | + | + |

| Mobility | ++ | ++ |

| Overhaul interval | 60,000 – 80,000 oph | 100,000 – 150,000 oph |

| CAPEX | +++ | +++ (simple cycle); ++ (combined cycle) |

| OPEX | ++ | + (simple cycle); +++ (combined cycle) |

| COD | Several weeks | Several months |

| Ambient temperature and altitude flexibility | +++ | O |

Choosing the right power generation technology

The specific requirements of your power generation project will determine which technology – gas engine or gas turbine – you ultimately choose. Each has its own strengths and weaknesses. A thorough analysis is essential to identify the best solution for your power generation needs. Use the table above and consider the following factors in your decision:

-

Efficiency

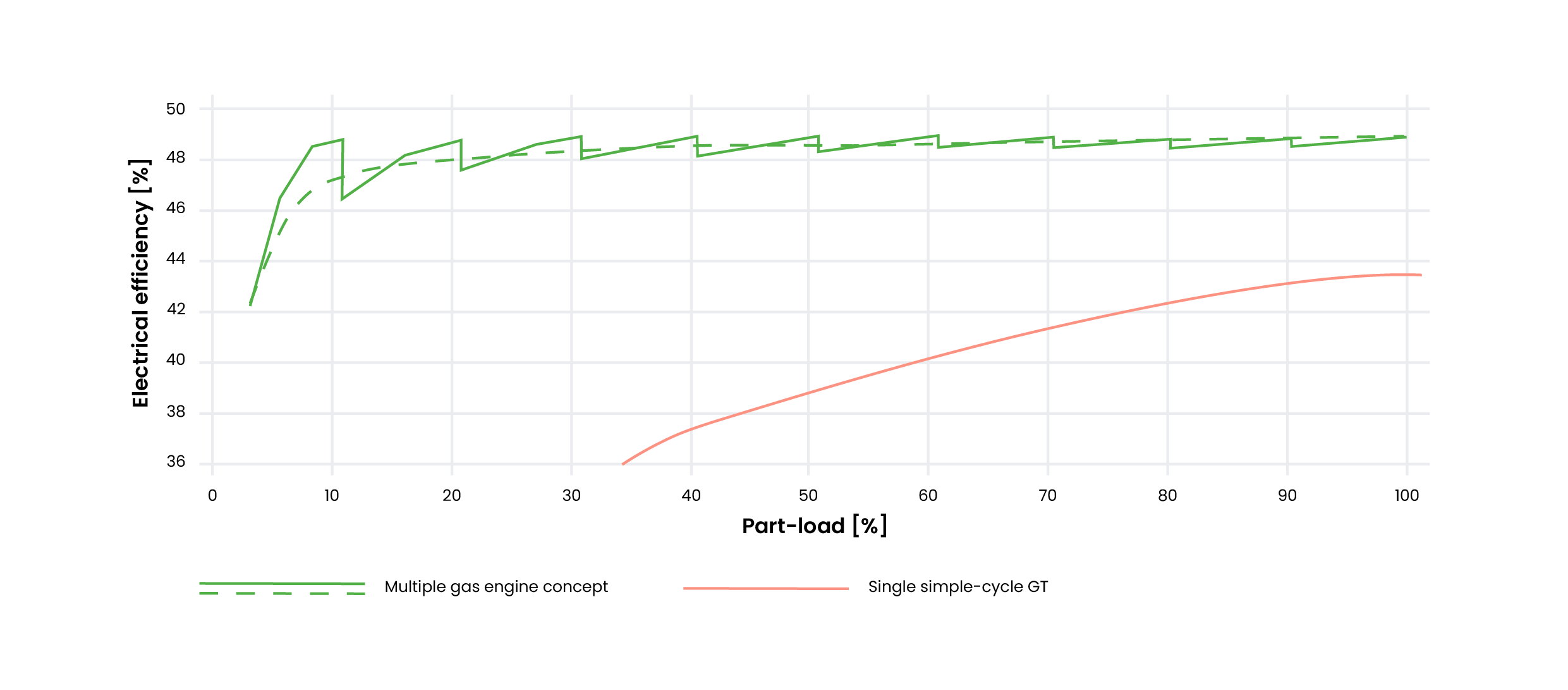

While gas turbines can achieve higher efficiencies than gas engines in combined cycle applications, gas engines offer higher electrical efficiency in simple cycle applications. CCGT setups typically require longer start-up times, which may make gas turbines a good choice for continuous base load power generation. On the other hand, gas engines tend to have better efficiencies at partial load, making them more suitable for applications with variable load profiles or for peaking power plants that need to ramp up and ramp down quickly. By cascading gas engines, plant efficiencies close to the nominal value can be achieved across a very large plant load range.

Source: INNIO Group

-

Flexibility

Gas engines can start and stop quickly, and they can ramp up and ramp down their power output rapidly. This makes them a good choice for applications requiring a high degree of flexibility, such as grid balancing or integration with renewable energy sources. Gas turbines, especially larger units and CCGT applications, require longer start-up and restart times.

Source: INNIO Group

-

Fuel type

Gas engines offer greater fuel flexibility and can operate on a wide range of gaseous fuels, but the specific fuel handling requirements can vary.

-

Size and scalability

Gas turbines are available in various sizes, from small microturbines to large industrial units. This makes them suitable for a wide range of power generation applications, from distributed generation to large central power plants. Although gas engines generally are found in small and mid-size power generation applications, they can be easily scaled up in size thanks to their modularity and are therefore also suitable for larger central power plant applications.

-

Gas pressure

Gas turbines, in general, are more sensitive to changes in fuel gas pressure. If the pressure is too low, it can affect the combustion process and reduce the efficiency and power output of the turbine. On the other hand, gas engines usually operate effectively over a wider range of gas pressures. Absolute gas pressure requirement is higher for gas turbines, especially at locations with low gas pressure (e.g. at distribution grids) the need for a gas compressor greatly increases parasitic loads for gas turbines.

-

CAPEX and OPEX

Gas engines generally have a lower upfront capital cost compared to gas turbines. They may require more frequent maintenance than gas turbines, but these tasks generally are simpler, therefore less costly and require shorter downtimes. Gas turbines have a higher initial CAPEX, though can operate for longer periods between servicing, but the maintenance tasks can be more complex and more expensive with extended downtimes. With proper maintenance, both technologies can have a similar lifespan.

-

Environmental impact

Gas engines and gas turbines typically have low emission values. However, further decarbonization is possible with additional emission control technologies such as SCR systems or by using carbon-neutral fuels like green hydrogen.

-

Altitude sensitivity

As the altitude increases, the air becomes less dense, which can reduce the power output and efficiency of both technologies. However, gas turbines generally are more affected by changes in altitude than gas engines. The two-stage turbocharging technology of gas engines enables stable power output even at higher altitudes. A capability that presents challenges for turbine technology to achieve.

-

Ambient temperature

Although higher ambient temperatures can reduce intake air density, which can, in turn, reduce the power output of both technologies, gas engines have significantly better performance than gas turbines at hot ambient temperatures. Gas turbines draw in large amounts of air for combustion, and temperature directly affects the density of this air. With control systems, the fuel-air mixture and ignition timing can be further enhanced to compensate for these changes, helping to maintain performance. Gas turbine power ratings are typically given as per ISO Standards at 15°C ambient temperature, and gas turbine technology specifies power output at ISO standard at 25°C. Two-stage turbocharging technology allows gas engines to run at full load power output at ambient temperatures well above 45°C. Through simple turbo charger adjustoment improved performance at high ambients can be achieved with gas engines whereas turbine technology needs to rely on active air inlet cooling, which involves additional costs and also consumes valueable resources like water.

The Jenbacher solution

Jenbacher 50 MW power plant

Advantages of Jenbacher engine technology:

- Efficiency: Gas engines can reach high levels of efficiency, particularly in combined heat and power (CHP) systems and high ambient temperatures and altitudes.

- Flexibility: Because they can be started and stopped quickly, gas engines respond efficiently to changes in power demand. In addition, gas engines can work in partial load mode as needed and are scalable in size.

- Environmental impact: Gas engines also can run on a broad range of energy sources, including renewable fuels such as biogas, industrial by-process gases, and even hydrogen of up to 100%.

- Modular solutions: The modular design and high engine reliability help increase uptime and low maintenance requirements of the power plant.

- Advanced digital solutions: myPlant AI-powered platform for remote monitoring and predictive analytics, helping to enhance performance and efficiency of gas engines fleet.

- Energy transition support: With the increasing share of renewable energy sources (RES) and decentralized power generation solutions, gas engines play a significant role in the energy transition by providing a flexible, efficient, and reliable power to the grid, ensuring stability in combination with variable renewable energy sources.

With more than 13,000 of our Jenbacher CHP systems delivered around the globe, INNIO Group is a global technology leader in engine-based power generation. Our Jenbacher experts can work with you to determine if gas engines are the right choice for your power generation project. And, with our wealth of experience, we can dive deeper into the costs and benefits of your project to find the solution that best meets your specific needs.

A Jenbacher cogeneration plant consists of the power generation unit with an engine and a generator along with heat exchangers to take advantage of the heat resulting from the combustion process. The energy systems use all related heat sources such as the engine cooling water, lubricating oil, the air/fuel gas mixture and the exhaust gas. Water temperature levels of 100°C and more can be achieved, making Jenbacher CHP and CCHP solutions highly flexible.

OUR EXPERTS ARE READY TO HELP YOU

Whether your business is looking for onsite power solutions, access to electricity, decreased energy costs, or even to sell electricity back to your local grid/consumers, Jenbacher´s regional experts can advise you on which solution makes the most sense for you.

Get in touch for free consultation on the following:

- The benefits of onsite power generation solutions for your company

- Potential financial benefits using economic modeling

- Consultation on the technical side of your project - fuel types, feasibility studies, equipment and balance of plant selection, and more

- Regional incentive programs relevant to your business

- Options to deliver your project: purchasing, financing and leasing, engaging a service provider (ESCO, BOO etc.)

- How to meet emissions targets

Fill-in contact form, or send us an email contact.en@innio.com.

Consult an expert

Send us a message and we’ll contact you to start the conversation.

Whether your business is looking for onsite power solutions, access to electricity, decreased energy costs, or even to sell electricity back to your local grid/consumers, Jenbacher regional experts can advise you on which solution makes the most sense for you.