Biogas Power Generation

You can find sustainability in your own backyard! Jenbacher reciprocating engines use biogas from the fermentation of organic waste to create heat and electricity. This reliable energy source can power your business today, tomorrow, and in the future.

How does it work?

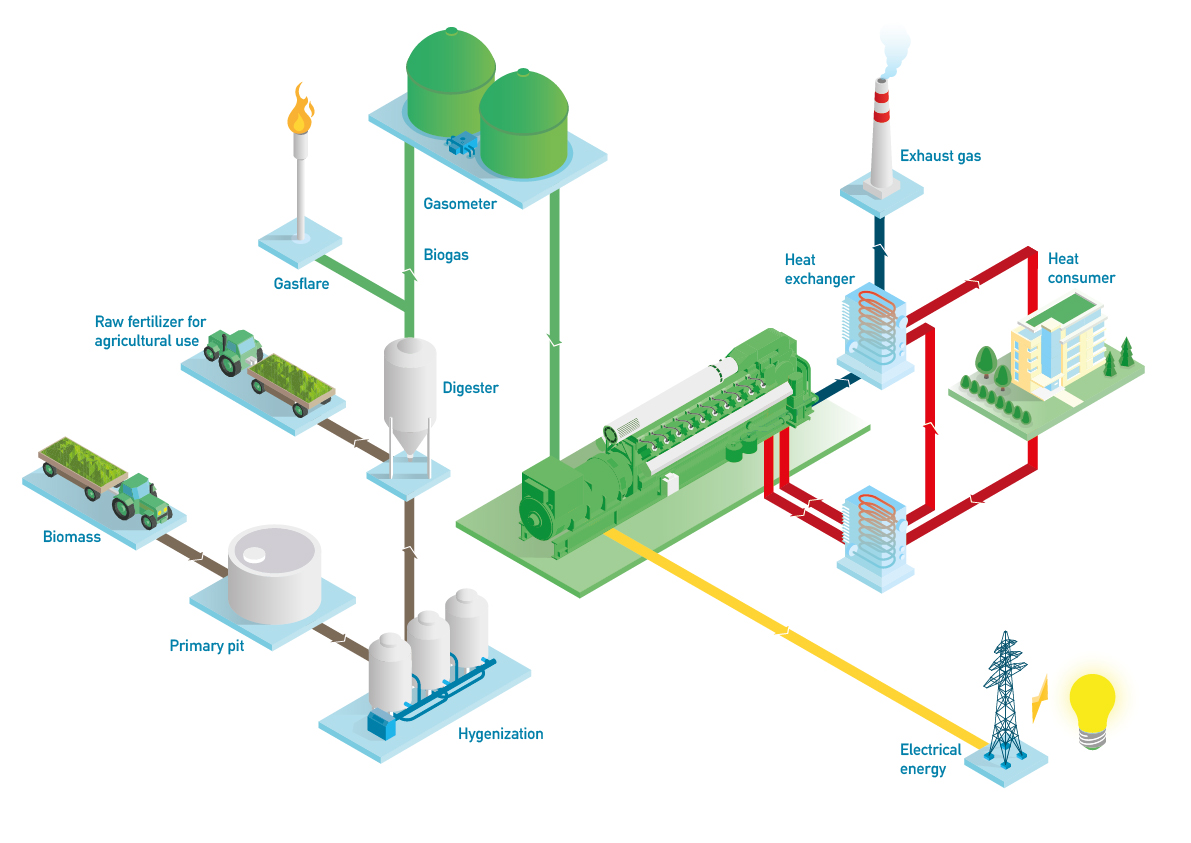

The process of biogas generation is divided into three steps: preparation of the bio-input, fermentation, and post-treatment of the residual material.

At the start, the organic material is collected in a primary pit, sterilized to remove harmful germs and moved to the digester. The biogas produced in the digester is collected in a gas storage tank, which helps ensure a continuous supply of gas, independent of fluctuations in gas production. Finally, the biogas is fed into a biogas engine. In case gas production is excessive, a gas flare should be installed for safety reasons.

Jenbacher biogas generator sets are widely used at farms and industrial sites around the globe. With biogas cogeneration, also called combined heat and power (CHP), onsite power plants can supply your business with its own electricity and heat needs while any excess electricity produced can be sold to the public grid.

Check out our video about on-farm biogas power project in New York state.

Tailor-made solutions for your operations:

-

Basically, Jenbacher biogas CHP systems include a biogas engine unit and heat exchangers that utilize the waste heat. INNIO can configure a wide range of heat sources—from biogas engine cooling water and oil to an air/fuel gas mixture and exhaust gas—to meet your individual needs.

-

Jenbacher CHP modules can be installed inside buildings or—for quicker onsite power generation—they can be packaged as ready-to-use containerized biogas solutions. All of our cogeneration plant solutions deliver flexible power generation and a high degree of reliability and availability.

Biogas engines

INNIO offers a comprehensive portfolio of Jenbacher biogas engines with power output from 335 kW up to 3,328 kW. A wide range of available generator voltage levels and flexible hydraulic integration variants is available to allow for excellent integration into your existing electrical and thermal systems.

Features & Benefits

- Highly efficient onsite power and heat generation with biogas

- Ready-to-use biogas power plant containerized solutions

- Lower carbon footprint with a green waste-to-energy/waste-to-power application

- Effective waste disposal alternative for dung, liquid manure, and biowaste, while simultaneously harnessing energy—a valuable substitute for conventional fuels

- Significant greenhouse gas reduction potential

- High-quality agricultural fertilizer in the remaining substrate—characterized by its neutralized acid, higher pH-value, retained nutrients, and lack of odor

OUR EXPERTS ARE READY TO HELP YOU

Whether your business is looking for onsite power solutions, access to electricity, decreased energy costs, or even to sell electricity back to your local grid/consumers, Jenbacher´s regional experts can advise you on which solution makes the most sense for you.

Get in touch for free consultation on the following:

- The benefits of onsite power generation solutions for your company

- Potential financial benefits using economic modeling

- Consultation on the technical side of your project - fuel types, feasibility studies, equipment and balance of plant selection, and more

- Regional incentive programs relevant to your business

- Options to deliver your project: purchasing, financing and leasing, engaging a service provider (ESCO, BOO etc.)

- How to meet emissions targets

Fill-in contact form, or send us an email contact.en@innio.com.

Consult an expert

Send us a message and we’ll contact you to start the conversation.

Whether your business is looking for onsite power solutions, access to electricity, decreased energy costs, or even to sell electricity back to your local grid/consumers, Jenbacher regional experts can advise you on which solution makes the most sense for you.

Resources & Downloads

Webinars - Food and Beverage CHP solutions (US)

Language: English

Category: Webinars

Jenbacher Webinars - Food and Beverage CHP solutions (US)